After getting the swingarm and chain replaced, I couldn't resist the call of the road and the beautiful autumn day. Regardless of the wet leaves, it's one of my favorite seasons for riding. I gathered up my gear, pushed the bike into the drive way, turned the petcock to ON and waited for the bowls to fill. Instead of a roaring inline four, I was given this:

More fuggin leaks. Seriously? After FULLY rebuilding the carbs, even the spendy Honda interconnecting o-rings. It ran great, with no leaks back in May. Unfortunately, I didn't put lines on the overflow tubes so I had no clue where the fuel was coming from and I didn't have any more fuel line. So, I pulled the tank, and put on the test tank. The leak stopped. WTH? Possible a stuck float, but I'm not counting it as fixed yet. One thing I did notice was pipe #2 was not hot, hmmmm. Along with a lack of fuel line, I also had no spare plugs to test. Come to think of it, did I replace the plugs previously?

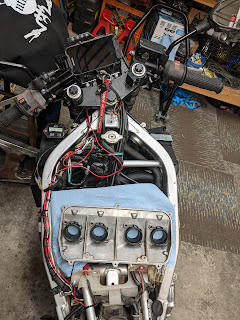

Nope, I did not replace the plugs. Now, I have a spare plug to use while checking spark (better than jamming a test light in there and jumping the ground). All 4 plugs have been swapped and the floats have been checked (again). I did add overflow tubes (with labels) so I can figure out which side is leaking without pulling the airbox.

Should be able to squeeze in a leak test this weekend. If the leaks continue, I'll swap out the floats (and or float valves) from the donor set of carbs. They were rebuilt many moons ago by my coworker who used to race a CBR600F in WERA. The rubber is probably long gone but hard parts should still be viable. While still frustrating, I'm still managing to find enjoyment in the work, which is a big change from the past.